- Contact Us

- +91-98111-55335

- [email protected]

Smart Water Management

December 4, 2019

Blockchain Needs to be a Part of a Larger Network

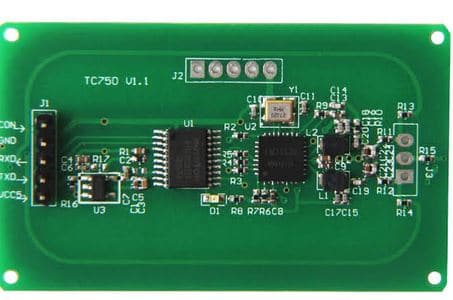

December 4, 2019RfId PCB Tags Creating and Protecting Value

RFID tags solve the challenges of barcodes by simultaneously reducing manual operations in the process

Radio frequency identification (RFID) tags provide reliability, higher reading accuracy, wide read angle, flexibility and read-through package. Information stored can be altered and occupies less space on the PCB (by replacing multiple barcode labels) due to its simplicity and fewer manual operations than barcodes. RFID is rewritable, and can also work without an optical connection through carton box, product housing, etc.

It covers all uses over the full value chain. Shorter wavelength of UHF results in minimal antenna space needed on PCBs. A device like Magicstrap can be added to design smart PCBs with RFID tag function. It enables products to be fully-traceable within the supply chain.

RFID is a battery-less RF technology with ultra-high frequency (UHF) range of 860MHz to 960MHz, which can cover not only a distance greater than five metres but also short-range communication. It has several advantages over barcode, such as cost saving, faster data capture (very short read time) and reading multiple tags at once (more than hundred tags per second).

RFID has overcome various challenges faced by businesses like piracy, traceability and wrong delivery of products, in addition to multiple manual operations.An RFID system has three elements, namely, tags, antenna and software system, and works in seven steps, as follows:

• Tag enters RF field of reader

• RF signal powers tag

• Tag transmits ID plus data

• Reader captures data

• Reader sends data to computer

• Computer sends data to reader

• Reader transmits data to tag

Shafi Ahmed, product engineer, Murata Electronics India Pvt Ltd, says “Magicstrap solves the challenges of tracking and after-sales service in a mass manufactured electronic products scenario. “By using a standard RFID reader, users can trace the products from fac-tory or warehouse to final shipments. They can design the software and GUI based on their needs and requirements. The reader has numerous other applications in asset tracking, anti-counterfeiting, retail and more.”

Magicstrap contains an RFID IC, an antenna filter to cover worldwide RFID frequencies, an antenna matching cir-cuit made of low-temperature cofired ceramics and electrostatic discharge protection (<2kV/mm). The antenna only receives incoming RF; all other functions like impedance matching, fixed centre frequency and bandwidth are provided by Magicstrap. There are four types of reference antennae on the PCB. Change of board size only affects communication range and not functionality. Materials for making PCB tags are ecofriendly and hundred per cent green. Tags connect all elements of the chain—R&D, production, logistics, distribution, point-of-sales and marketing, aftermarket and recycling. These provide near-field transmission with loop antenna, for which the user only needs to control the process.

There are four recommended anten-na patterns to a PCB when using a device like Magicstrap. To gather practical experience or test possible performance before touching the layout of the PCB and adding one of these patterns permanently, a mini PCB can be used. A mini PCB should ideally be used at the location where the user plans to later integrate Magicstrap antenna pattern in the layout. Magicstrap should be mounted as close as possible to the middle of the PCB so that maximum read range can be achieved. The same is valid for the mounting position of the mini PCB.

To communicate with only one Magicstrap, it is important to make sure that there is no other RFID tag present in the field of the reader. To test bulk read function, the user can place as many tags in the field as needed.RFID is compatible with EPC Global standard C1G2 and with any EPC Global C1G2-compliant equipment.

It carries 240-bit EPC for serial and additional 512-bit memory. It enables users to freely add their own information (pro-duction date, version ID, etc), while keeping their own numbering system internally. It is ISO 18000-6-compliant and UHF air interface standardised.